HONBLE MINISTER GIRIRAJ SINGH AND COLORJET CHAIRMAN DISCUSS SUSTAINABILITY AND MAKE IN INDIA IN TEXTILPRINTING

Delhi, India:17 FEB, At Bharat Tex 2025, one of India’s most significant textile industry events, Mr.M.S. Dadu, Chairman of ColorJet Group, had a meeting ...

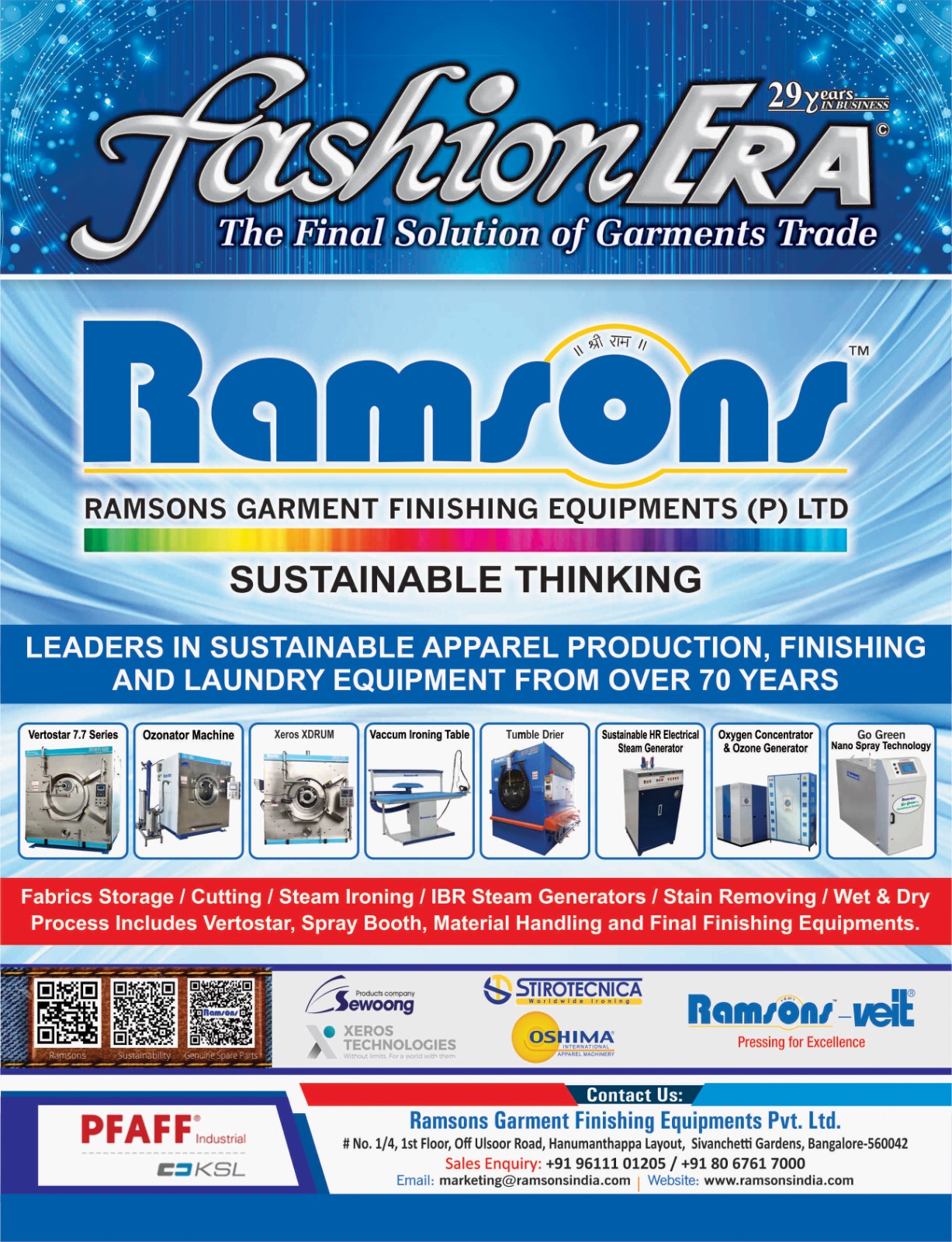

.jpg)

.jpeg)